Quality

Quality Lab Capabilities

I. Tests and Evaluations

The laboratory has the ability to verify the following:

A. Hardness: Surface hardness , Core hardness, Hardness at specified locations

Scales: C, D, A, G, B, F, K, E, H, P, L, V, S, R, 15N, 30N, 45N, 15T, 30T, 45T,

15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y

B. MacroVickers Hardness 1, 2, 3, 5, 10, 20, 30 & 50 Kgf

C. MicroVickers Hardness 25g-1000g Loads using diamond indenters (HV) and Knoop indenters (HK)

D. Effective Case Depth (ECD) at prescribed locations

E. Total Case Depth (TCD) at prescribed locations

F. Microstructure evaluation

G. Appearance per customer request

H. Dimensions per customer request, hand measurement or CMM

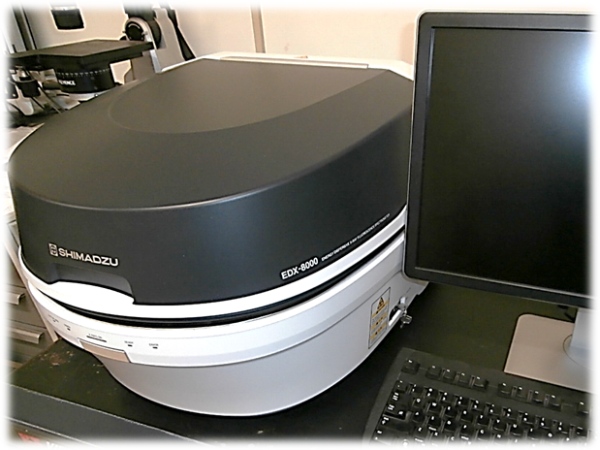

I. EDX-8000 Energy Dispersive X-Ray Spectrometer (Material Composition Analysis)

J. Surface Roughness

II. Inside Verifications/Calibrations

A. Rockwell/Vickers Hardness Test Unit Accuracy Verification (Daily Check as specified by ASTM E-18)

B. MicroVickers Test Unit Accuracy Verification (Daily Check as Specified by ASTM E-384)

C. Dimensional Equipment Accuracy Verification (Micrometers, Calipers, CMM, customer gages etc.)

III. Outside Verifications/Calibrations

A. Hardness Test Units

B. Dimensional Measuring Equipment used for Measurements that determine if product satisfies customer or internal requirements.

IV. Equipment List

3 Wet cutoff saws

2 Dual mounting presses

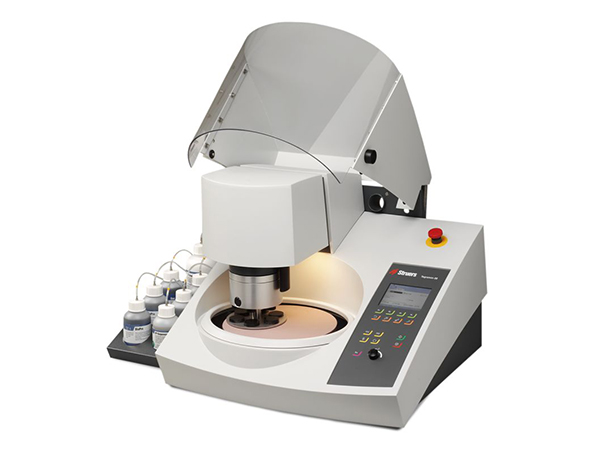

2 Automated grinding/polishing machines

1 Manual microhardness testing machine

2 Automated microhardness testing machines

3 Rockwell type hardness testing machines

1 Macro Vickers type hardness testing machine

1 digital microscope with measuring and photo capabilities

1 EDX-8000 Energy Dispersive X-Ray Spectrometer

V. Methods and Standards (Current Revisions)

A. ASTM E-18 Standard Test Methods for Rockwell Hardness and Superficial Hardness of Metallic Materials

B. ASTM E-384 Standard Test Methods for Knoop & Vickers Hardness of Materials

C. ASTM E-140 Standard Conversion Tables for Metals

D. ASTM E-3 Standard Practice for Preparation of Metallographic Specimens

E. ASTM E-29 Standard Significant Digits in Test Data to Determine Conformance with Specifications

F. ASTM F-1375 EDX Analysis of Surface Condition

G. Various customer standards as required